Mhs - Material Handling Supply Inc. Fundamentals Explained

Mhs - Material Handling Supply Inc. Fundamentals Explained

Blog Article

The 9-Minute Rule for Mhs - Material Handling Supply Inc.

Table of ContentsGetting My Mhs - Material Handling Supply Inc. To WorkMhs - Material Handling Supply Inc. for BeginnersIndicators on Mhs - Material Handling Supply Inc. You Need To KnowMhs - Material Handling Supply Inc. Can Be Fun For EveryoneIndicators on Mhs - Material Handling Supply Inc. You Need To KnowMhs - Material Handling Supply Inc. Fundamentals ExplainedMhs - Material Handling Supply Inc. Things To Know Before You Buy

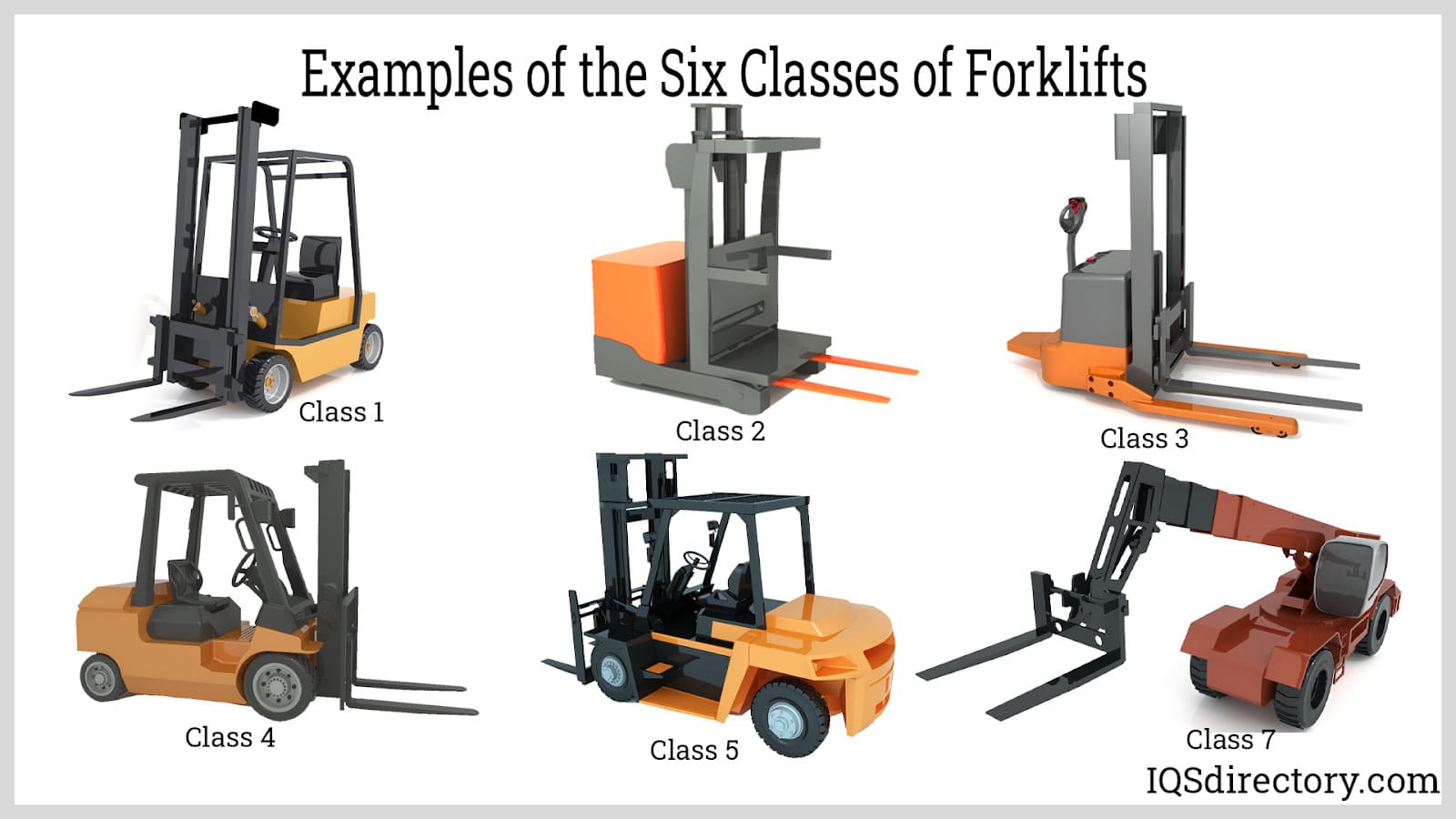

As a whole, this tools is most often used in a commercial setup to move goods and products. There are 4 major kinds of material handling tools that assist stockrooms and factories relocate and save products, which are: Transport Devices Positioning Tools Device Lots Development Tools Storage Devices Industrial trucks, like forklifts, fall under material handling equipment and are used to move heavy materials securely.

Compared to standing making use of a stand-up rider. Specifically when raising and lowering. Harsh terrain forklifts are constructed to function at building and construction websites or other locations on uneven surface areas.

How Mhs - Material Handling Supply Inc. can Save You Time, Stress, and Money.

When it pertains to material handling forklifts, telehandlers can reach the greatest elevations and lug one of the most weight - forklift rental near me. With a narrow aisle forklift, you can do more with much less room. Slim aisle forklift vehicles are made to be utilized in aisles that measure less than 10 feet by 12 feet

An is a type of material handling tools used to select and deliver goods from storage space for orders. Additionally, order pickers allow drivers conveniently and promptly pick products from bins of different SKUs for order fulfillment. are the simplest kind of forklift and are utilized to move pallets in warehouses.

Hands-on pallet jacks are hand-operated while electrical pallet jacks are battery-powered. Both relocation goods brief distances. An also called a, is a mechanized forklift used to help building employees within high altitudes for tasks and projects. There are a number of various kinds of airborne lifts that are created for various building tasks which we've listed here.

Some Known Details About Mhs - Material Handling Supply Inc.

Using them, business workers can get to raised heights or hard-to-reach locations comfortably. Considering that there are lots of kinds of boom lifts, it's important to discover the various attributes and features of each.

These automobiles lift people into the air safely in order to perform jobs. are aerial lifts designed to operate in very limited and confined rooms. The combination of high lifts, reach, and versatility of these platforms makes them a risk-free service. These upright mast lifts attribute wheels, therefore making it simple to move and carry the light-weight maker.

The Ultimate Guide To Mhs - Material Handling Supply Inc.

Forklift is composed of range of elements called for to manage the task efficiently (http://go.bubbl.us/e1b7ac/5d6f?/New-Mind-Map). From Vehicle Structure, power site web resource to weight are necessary for the forklift to work efficiently.

The Counterweight is a cast iron weight connected to the back component of the forklift. On Electric Forklift, Counterweight is repaired to the lead-acid battery.

The carriage serves as the base to the forklift. The Mast is a vertical part that lifts up and pushes down the lots.

The 5-Second Trick For Mhs - Material Handling Supply Inc.

Air gets entrapped through the base of the cylinder that enables gasses to get in without dripping them out. This force triggers the piston to move up, increasing the volume of the gas and lessening the pressure.

The Driver presses the manage in an ahead direction, indicating the forklift to pump excess air to the cylinders. The driver draws the handle in backwards instructions that signals an unique valve to discharge gas from cylinders. The hydraulic pistons are connected to the 2 primary upright structures called "masts".

Thus, when the hydraulic pistons push the poles in upward instructions, the gears on the poles is pressed against the roller chains. It happens because the one side of the chain is repaired to the stationary frame of the forklift, and the only method by which poles can move upward is when equipments rotate in clockwise instructions and pull the forks expenses.

Facts About Mhs - Material Handling Supply Inc. Revealed

There are 2 pairs of additional hydraulic cyndrical tubes connected to the base of the poles. Once the Tilt Take care of is relocated ahead instructions, the air immediately fills the chamber (forklift rental near me). The increase in stress is sufficient to press the head of the piston and let the masts quit the vehicle's body

Unknown Facts About Mhs - Material Handling Supply Inc.

When the pistons are pressed onward, the masts are pushed back to the car. Forklifts have entirely changed the storage space and shipping markets. Forklifts were very first developed during very early part of the 20th century and currently had actually become a vital component of the contemporary industrial world. Forklifts are called after their fork-like prongs that raise the load.

Report this page